SMG-Global Circuits Quality Policy & ITS Objectives

To achive total customer satisfaction through teamwork, continuous improvement, and delivering defect free product on time. Management of SMG-Global circuits Corporation is committed to comply with the requirements of a quality syste,. SMG-Global Circuits adheres to all applicable standards and customer specific requirements and endeavors to provide processes that ensure we achieve this in order to build a robust and world-class business.

Customer satisfaction

Achieved through delivering a defect free product on time.

Employee proficiency

Employee proficiency and job satisfaction-Achieved through awareness, teamwork, training and development programs.

Community

We comply with all applicable safety, environmental, legal and regulatory requirements.

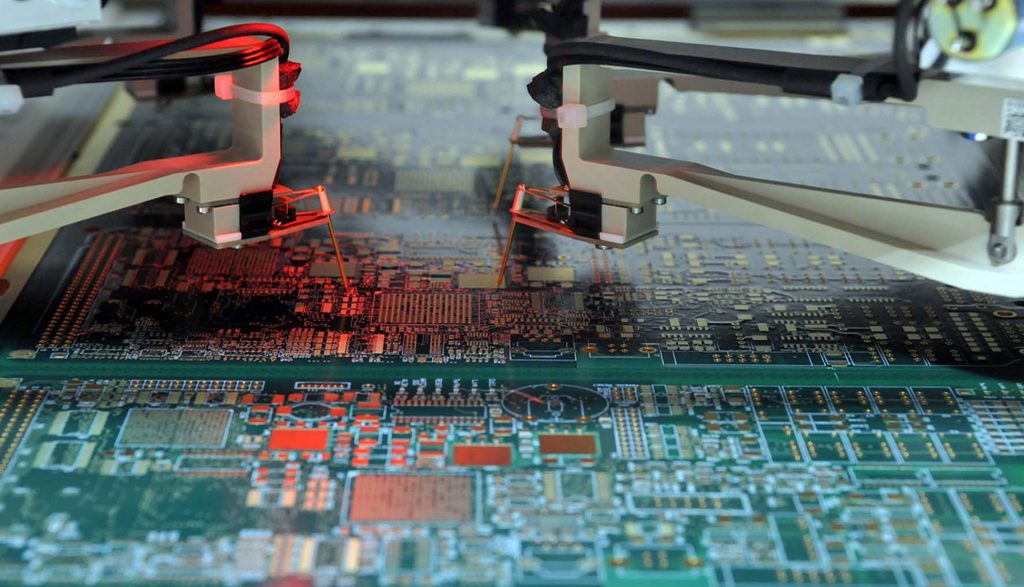

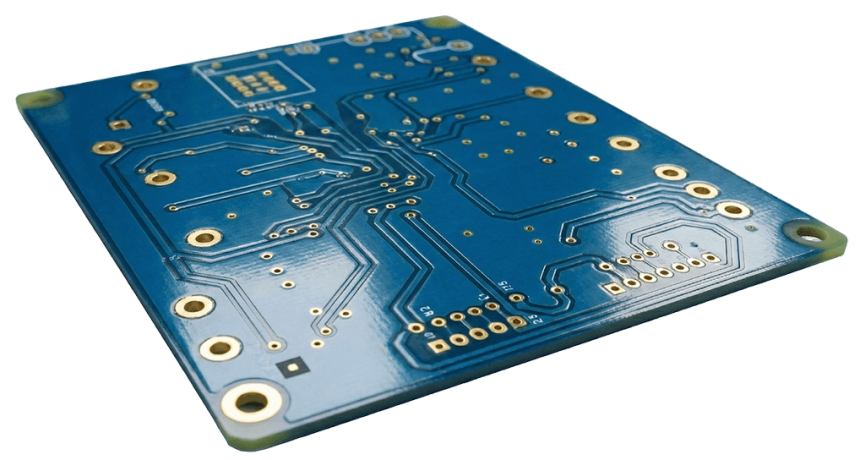

Circuit Board Testing Procedures That Meet ISO Certification Standards

SMG Global believes in stringent circuit board testing procedures to ensure the highest quality PCB products for their customers. In addition to testing procedures, we are transparent with our reports and certificates, allowing our customers to see the excellent results of our strict quality assurance methods for themselves.

SMG Global is proud to meet international quality standards through our ISO 9001:2015 certification. In the past, we have consistently attained the most current version of this accreditation, keeping up to date with top industry practices. The current quality certificate we hold includes acceptable criteria for IPC-A-600 Class-2 & 3, and performance specifications of IPC-6012 Class-2 & 3 UL 796, 94V-0. Both of these requirements are considered the latest revisions of current ISO accreditation standards.

IPC-356A Gerber Netlist Circuit Board Testing Standard

The IPC-356A Gerber Netlist Testing Standard is a procedure that tests circuit boards using a CAM program. This program evaluates if a printed circuit board design will be electrically functional. If, after the testing procedure, the CAM program discovers errors, the design discrepancies are located, eliminating miscalculations before they get to production.

QUALITY

Our Procedure for Bare Circuit Board Testers

- 150 Volts

- 5 Ohms Continuity

- 100 Mega Ohms Isolation

Our Procedure for Flying Probe Circuit Board Testers

- Up to 250 Volts

- 6 Ohms Continuity

- 100 Mega Ohms Isolation

Certificates & Quality Reports Available

Our certificates and reports further assure our customers of SMG Global’s quality standards. We don’t cut corners when it comes to testing our circuit boards, as evidenced by our extensive list below:

- Base Laminations According to IPC-4101

- Ionic Contamination According to IPC-6012

- Electrical Test According to IPC-9252

- Solderability According to J-STD-003

- Micro-section Evaluation

- Thermal Stress Evaluation

- X-Ray Fluorescence & Capacitance Plating Thickness

- EDAX & SAM By Request

- Impedance Control

- Atomic Absorption Unit

Why We Prioritize Our Circuit Board Testing Procedures

We take our circuit board testing procedures seriously because we take quality seriously. At SMG Global our goal is simple: To provide our customers high-quality, defect-free printed circuit boards alongside value-added services at competitive prices. Moreover, we deliver these high-caliber products in a timely manner. SMG Global constantly implements new technologies, processes and circuit board testing features to meet today’s competitive electronic market place.

quality

Certified Quality. Guaranteed Compliance

Our commitment to quality is validated by stringent international standards. We maintain ISO 9001:2015 certification and adhere to specialized requirements like ITAR compliance. View our certifications.

ISO 9001:2015

Validates our robust quality management systems, ensuring consistent execution and continuous improvement across every stage of our manufacturing process.

UL CERTIFICATE

Certifies that our circuit boards meet rigorous global safety and flammability standards, a critical requirement for product reliability and market access.

ITR CERTIFICATE

Authorizes us to handle sensitive defense and aerospace technology, guaranteeing strict adherence to U.S. export control regulations and data security.